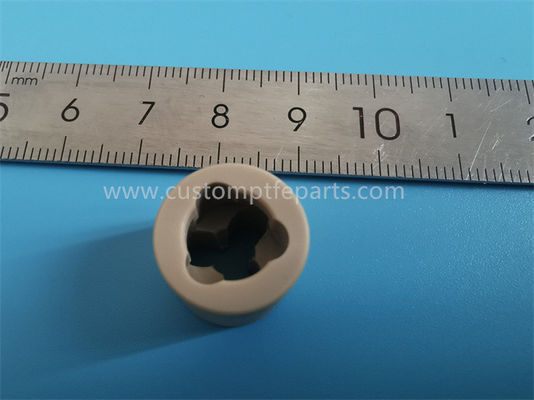

PEEK (polyether ether ketone) is a high-performance thermoplastic material that is known for its exceptional mechanical and thermal properties. One of the many applications of PEEK is in gear screws, where it is valued for its strength, durability, and resistance to wear.

PEEK gear screws are used in a wide range of industries and applications. In the automotive industry, they are used in high-performance engines, transmissions, and other components that require strength and durability. PEEK gear screws are also used in the aerospace industry, where they are used in aircraft engines, landing gear systems, and other critical components that require high strength and temperature resistance.

In the medical industry, PEEK gear screws are used in a variety of medical devices and equipment, including surgical instruments, implantable devices, and drug delivery systems. PEEK is biocompatible, meaning it is safe for use in the human body, and has excellent chemical resistance, which makes it ideal for use in medical applications.

PEEK gear screws are also used in industrial machinery, including pumps, compressors, and other equipment that requires high strength and temperature resistance. PEEK is known for its excellent resistance to wear, which makes it ideal for use in these types of applications.

Another important application of PEEK gear screws is in the electronics industry, where they are used in a variety of components, including connectors, switches, and circuit boards. PEEK is an excellent electrical insulator and has a high dielectric strength, which makes it ideal for use in these types of applications.

PEEK gear screws also have a number of unique properties that make them well-suited for a wide range of applications. PEEK has a high strength-to-weight ratio, meaning it is very strong for its weight, which makes it ideal for use in applications where weight is a critical factor. PEEK also has a high melting point and can withstand high temperatures, which makes it suitable for use in high-temperature environments.

In summary, PEEK gear screws are used in a wide range of industries and applications, including automotive, aerospace, medical, industrial machinery, and electronics. PEEK is valued for its strength, durability, resistance to wear, biocompatibility, excellent chemical and electrical properties, and high temperature resistance. These properties make PEEK gear screws ideal for use in critical applications where reliability and performance are essential.

PolyEtherEtherKetone (PEEK)

Maintains wear resistance and mechanical strength up to 480°F continuous use.

PEEK is the performance material of choice for aggressive environments such as high temperatures, wet processes, and heavy loads. It combines exceptional wear, chemical and moisture resistance with very high strength, dimensional stability and stiffness. PEEK can be continuously exposed to hot water or steam with no distortion, corrosion or galling.

Unreinforced PEEK is a general purpose material noted for its high elongation and toughness. Glass fiber-reinforced PEEK offers increased strength, stiffness and stability at high temperatures, while carbon fiber-reinforced PEEK gives designers the benefit of excellent compression strength and stiffness and reduced expansion rates. PEEK is easily machined to precise tolerances.

| UNITS | ASTM TEST | PEEK | PEEK 30% GLASS-FILLED |

|

|---|---|---|---|---|

| Tensile strength | psi | D638 | 14,000 | 24,620 |

| Flexural modulus | psi | D790 | 590,000 | 1,450,000 |

| Izod impact (notched) | ft-lbs/in of notch | D256 | 1.6 | 1.84 |

| Heat deflection temperature @ 264 psi |

°F | D648 | 306 | 599 |

| Maximum continuous service temperature in air |

°F | 480 | 482 | |

| Water absorption (immersion 24 hours) |

% | D570 | 0.50 | 0.11 |

| Coefficient of linear thermal expansion | in/in/°Fx10-5 | D696 | 2.6 | 1.2 |

| Coefficient of friction (dynamic) | 0.25 | 0.30 |