-

High Light

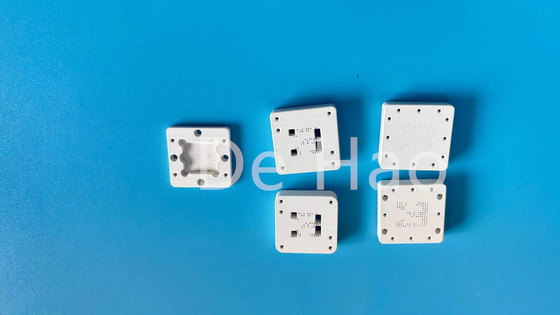

Sockets PEEK Machined Parts

,PAI CNC Machining Parts

,PPS CNC Machining Parts

-

Tolerance±0.02mm

-

MOQ1000 Piece

-

Surface TreatmentPolishing, Sandblasting, Anodizing, Etc.

-

ColorBlack, White, Etc.

-

Processing MethodCNC Machining,drilling Machining

-

MaterialPEEK-filled With Ceramic

-

SizeCustomized

-

Lead Time7-15 Days

-

Place of OriginKunShan

-

Brand NameDeHao

-

Model NumberDH630

PPS PEEK PAI CNC Machining Parts For Sockets

Product Description:

High temperature resistance: High temperature resistance of PPS, PEEK and PAI materials, suitable for chip testing in high temperature environments.

Mechanical strength: The excellent mechanical strength of PPS, PEEK and PAI materials provides stable mechanical support and reliable connections.

Wear resistance: The wear resistance of PPS, PEEK and PAI materials can maintain long-term stable performance in frequently plugged and unplugged test environments.

Electrical properties: The excellent electrical properties of PPS, PEEK and PAI materials ensure good electrical contact and accurate test results.

Chemical stability: The chemical stability of PPS, PEEK and PAI materials, which can resist chemical corrosion and solvent erosion, and maintain long-term stability.

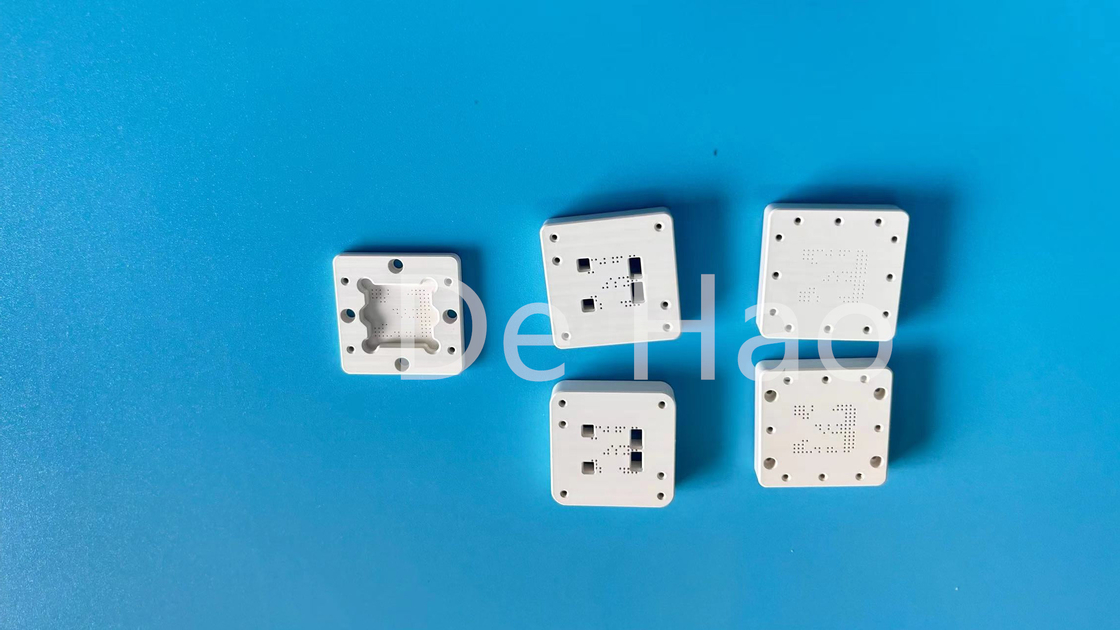

Precision machining: The precision machining capability of PPS, PEEK and PAI materials ensures the accuracy and match of part sizes and provides a stable test environment.

High reliability: The high reliability of PPS, PEEK and PAI materials provides reliable performance and long life under harsh test conditions.

Adaptability: The adaptability of PPS, PEEK and PAI materials provides flexible solutions to the needs of different chip packages and test platforms.

Features:

- Product Name: PEEK Machined Parts

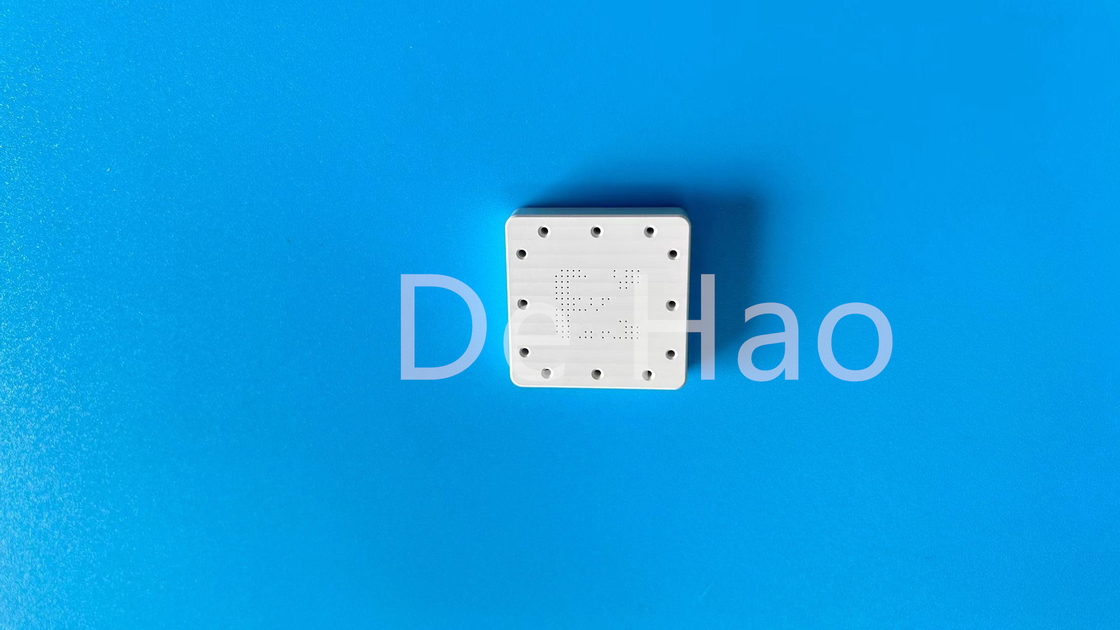

- Tolerance: ±0.02mm

- Processing Method: CNC Machining,drilling Machining

- MOQ: 1000 Piece

- Material: PEEK-filled With Ceramic

- Heat Treatment: Yes

- Special Feature: PEEK-ceramic filled, aging test, socket set screws

Technical Parameters:

| Parameters | Details |

|---|---|

| Application | Industrial, Automotive, Medical, Etc. |

| Packaging | Carton, Etc. |

| Tolerance | ±0.02mm |

| Material | PEEK-filled With Ceramic |

| Processing Method | CNC Machining, drilling Machining, micro-hole CNC, socket |

| Color | Black, White, Etc. |

| Size | Customized |

| MOQ | 1000 Pieces |

| Heat Treatment | Yes |

| Lead Time | 7-15 Days |

Applications:

The DeHao DH630 PEEK Machined Parts are specially designed for high-precision applications in the semi-conductor industry and other industrial applications. The parts are machined from PEEK-filled with ceramic material, and are given a surface treatment such as polishing, sandblasting, or anodizing. The MOQ for this product is 1000 pieces, and it is packaged in cartons. Heat treatment is available for this machined part. The DeHao DH630 PEEK Machined Parts are ideal for use in precision socket, as well as other high-precision applications. The high-performance ceramic filled PEEK material is suitable for a variety of industrial applications, and is especially beneficial for semi-conductor industry.

Customization:

- Brand Name: DeHao

- Model Number: DH630

- Place of Origin: KunShan

- Packaging: Carton, Etc.

- Lead Time: 7-15 Days

- Surface Treatment: Polishing, Sandblasting, Anodizing, Etc.

- Application: Industrial, Automotive, Medical, Etc.

- Color: Black, White, Etc.

- Specialized in semi-conductor, micro-hole CNC and aging test.

Support and Services:

At PEEK Machined Parts, we take pride in our commitment to providing exceptional technical support and service. We offer a variety of technical solutions and services to help you get the most out of your machined parts.

We provide a wide range of technical solutions to help you get the most out of your machined parts. Our team of experts can provide advice and assistance on a variety of topics, including:

- Design and engineering

- Material selection

- Manufacturing processes

- Quality control

- Performance testing

Our team of experts is available to provide technical support and assistance whenever you need it. We can provide advice on the best materials and processes for your application, as well as help troubleshoot any problems you may encounter.

At PEEK Machined Parts, we stand behind our products. We offer a variety of product warranties to ensure that your machined parts are of the highest quality.

Packing and Shipping:

PEEK machined parts are packaged in sealed plastic bags. The parts are then placed in a cardboard box or plastic container and shipped via UPS, FedEx, or DHL.

FAQ:

A1.The brand name of DeHao Machined Parts is DeHao.

A2.The model number of DeHao Machined Parts is DH630.

A3.DeHao Machined Parts is from KunShan, China.

A4.The material of DeHao Machined Parts is aluminum alloy.

A5.The surface treatment of DeHao Machined Parts is sandblasting.