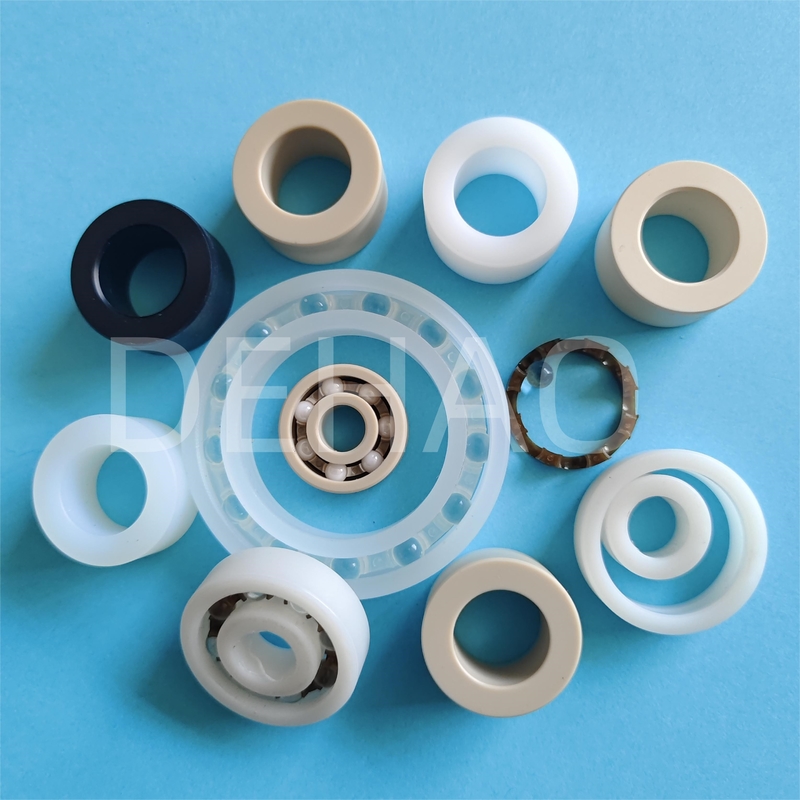

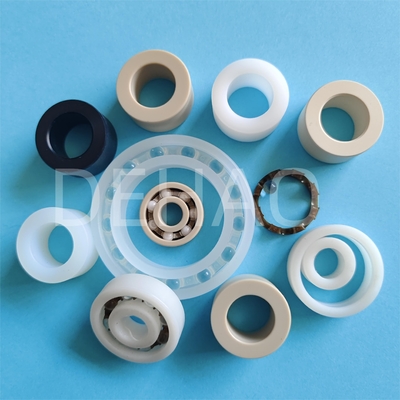

Non Metallic PEEK Nut Gasket For Seft Lubricant Plastic Bearing Shaft Sleeve

-

High Light

Smooth PEEK Nut Gasket

,Non Metallic PEEK Gasket

,Self Lubricant Bearing PEEK Nut Gasket

-

Heat Conductivity≤0.25W/m.K

-

Dielectric Strength≥20KV/mm

-

CertificateISO9001

-

ApplicationMachinery Parts

-

Tolerance±0.01mm

-

ShapeCustomized

-

Surface TreatmentSmooth

-

Hardness60~80 Shore D

-

Place of Originkunshan

-

Brand Namedehao

Non Metallic PEEK Nut Gasket For Seft Lubricant Plastic Bearing Shaft Sleeve

Product Description:

Features:

- Product Name: PTFE Machined Parts

- Material: PTFE

- Dielectric Strength: ≥20KV/mm

- Temperature Resistance: 260℃

- Chemical Resistance: Good

- Size: Customized

- Highly Durable PTFE Machining Elements

- Precisely Machined PTFE Components

- Reliable PTFE Machining Elements Supplier

Technical Parameters:

| Attribute | Value |

|---|---|

| Heat Conductivity | ≤0.25W/m.K |

| Shape | Customized |

| Hardness | 60~80 Shore D |

| Application | Machinery Parts |

| Chemical Resistance | Good |

| Temperature Resistance | 260℃ |

| Size | Customized |

| Certificate | ISO9001 |

| Friction Coefficient | 0.04~0.20 |

| Material | PTFE |

Applications:

dehao's PTFE Machined Parts are ideal for industrial applications and scenarios where high precision and superior performance are required. Our PTFE Machined Parts are customized to your exact specifications and come in a variety of sizes, with a hardness ranging from 60 to 80 Shore D and a dielectric strength of more than 20KV/mm. Our PTFE Machined Parts come with a smooth surface and a friction coefficient of 0.04 to 0.20.

Our PTFE Machined Parts are the perfect choice for a wide range of applications, such as in the automotive, aerospace, medical, and electronic industries. Our Machined PTFE Components are highly durable and temperature resistant, making them suitable for extreme circumstances and environments. Our Machining Elements are also resistant to chemicals and corrosion, ensuring a longer product life and better performance.

Our Machined PTFE Components are manufactured in our Kunshan facility and have been rigorously tested to ensure quality and performance. As a leading Machined PTFE Components Manufacturer, we guarantee our products are of the highest standard and deliver superior performance. Our Machined PTFE Components are the perfect solution for any application requiring precision and performance.

Customization:

dehao provides custom machined PTFE parts with excellent temperature resistance up to 260℃ and tight tolerance of ±0.01mm. Our machined PTFE components are made of PTFE material with hardness of 60~80 Shore D, making them ideal for a wide range of machinery parts.

Our machined PTFE parts are ideal for various industries which require high temperature resistance and tight tolerance. The machined PTFE parts are designed and manufactured considering the application and customer requirements.

If you need PTFE machining elements or custom machined PTFE parts, contact us today to learn more about our services.

Support and Services:

Technical Support and Service for PTFE Machined Parts

- 24/7 technical support and service

- Expert advice on product selection

- Assistance with installation and troubleshooting

- Maintenance and repair services

- Quality control and assurance

- Replacement parts and components

- Product customization