-

High Light

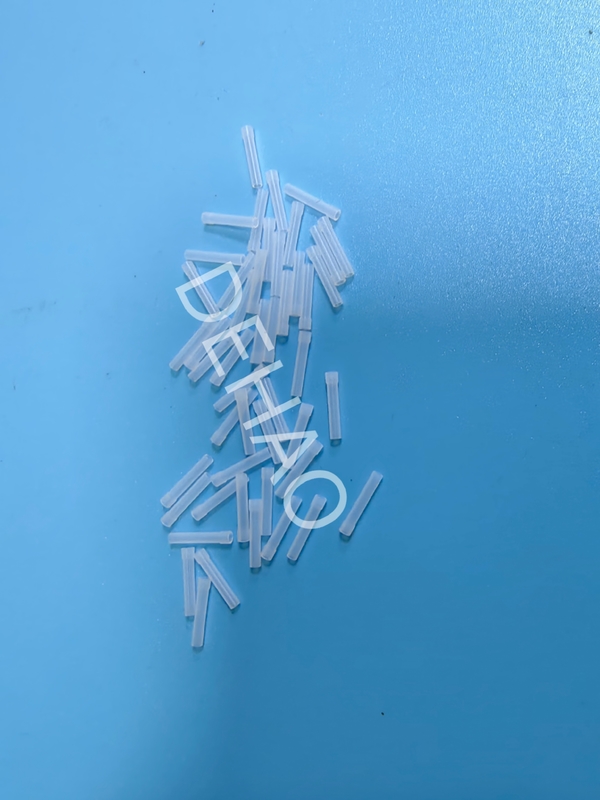

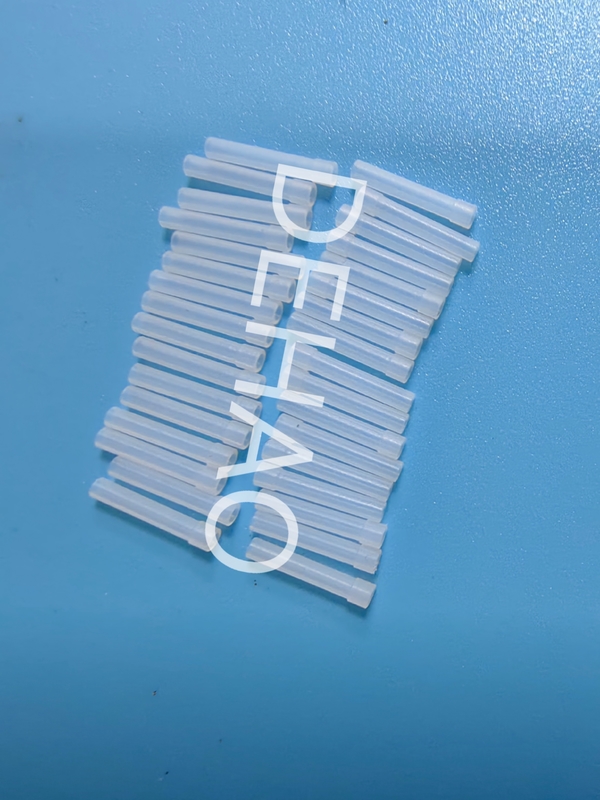

Radiofrequency Ablation Needle PTFE Insulator

,Smooth PTFE Insulator

,Custom PTFE Parts 14Mpa

-

Loss Tangent≤0.001

-

Surface TreatmentSmooth

-

ColorWhite

-

HardnessSoft

-

Tensile Strength≥14Mpa

-

SizeCustomized

-

Elongation≥150%

-

Tolerance±0.01mm

-

Place of OriginKunShan

-

Brand NameDeHao

-

CertificationISO9001

-

Minimum Order Quantity2K

-

Delivery Time7-15days

-

Payment TermsTT

Smooth PTFE Insulator For Radiofrequency RF Ablation Needle

Product Description:

The structure of an RF ablation needle typically consists of the following components:

Electrode Tip: The electrode tip is the key component of the RF ablation needle, usually made of a conductive material such as stainless steel, platinum, or other alloys. It is responsible for delivering high-frequency electrical energy to the target tissue. The electrode tip is often designed with a tapered, sharp, or spherical shape for easier insertion into the tissue.

Connector Wire: The connector wire connects the RF generator to the electrode tip. It is typically made of a conductive material such as copper or other conductive metals. The connector wire transmits the high-frequency electrical energy from the generator to the electrode tip.

Insulation Material: Insulation material covers the portion of the connector wire to prevent electrical energy leakage or unnecessary heat damage to the surrounding tissue. Common insulation materials include polyetheretherketone (PEEK), polytetrafluoroethylene (PTFE), and others.

Connector: The connector is located at the end of the connector wire and is used to connect with the RF generator. The connector typically has a specific design and insertion method to ensure a secure connection and prevent accidental detachment.

In addition to these components, an RF ablation needle may also include other auxiliary parts, such as a cooling system (to cool the electrode tip to control the temperature of the treatment area) or RF electrodes (to assist with electrical energy transmission). The specific configuration may vary depending on the application and the design of the manufacturer.

It is important to note that an RF ablation needle is a specialized medical device and should only be operated by experienced healthcare professionals following the appropriate operating procedures and safety requirements.

Features:

Technical Parameters:

Applications:

Customization:

Custom PTFE Parts provided by DeHao are made with top quality materials and are certified with ISO9001. They are manufactured in KunShan and are highly resistant to erosion and oxidation. The product have superior dielectric strength ≥20KV/mm and dielectric constant 2.1-2.2, and tolerance of ±0.01mm, and loss tangent ≤0.001. The product have excellent M111 hardness and flexibility, giving them the ability to withstand extreme temperatures and pressures. A minimum order quantity of 2K is required and the delivery time is within 7-15days. Payment terms are TT.

Support and Services:

We provide technical support and service for our Custom PTFE Parts. Our experienced engineers are available to provide technical advice, design and engineering support, and troubleshooting assistance.

We are committed to providing our customers with the highest quality products and services, and we strive to exceed your expectations. Our technical support team is available to answer any questions you may have about our Custom PTFE Parts, and to provide guidance and assistance in the selection and application of the product.

In addition to offering technical support, we also offer a full range of repair and maintenance services. Our experienced technicians can provide on-site repairs and maintenance of Custom PTFE Parts, ensuring that your products are functioning properly and performing to their fullest potential.

If you have any questions or need assistance with our Custom PTFE Parts, please contact us and we will be happy to help.