-

High Light

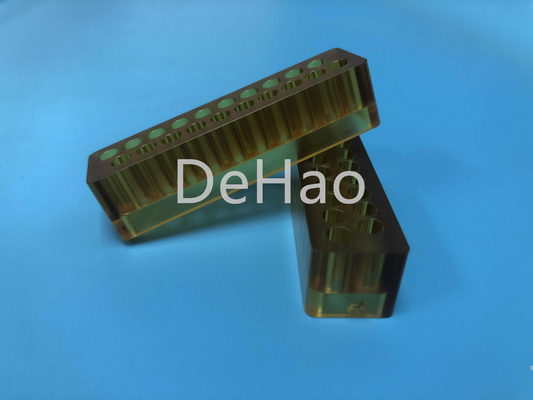

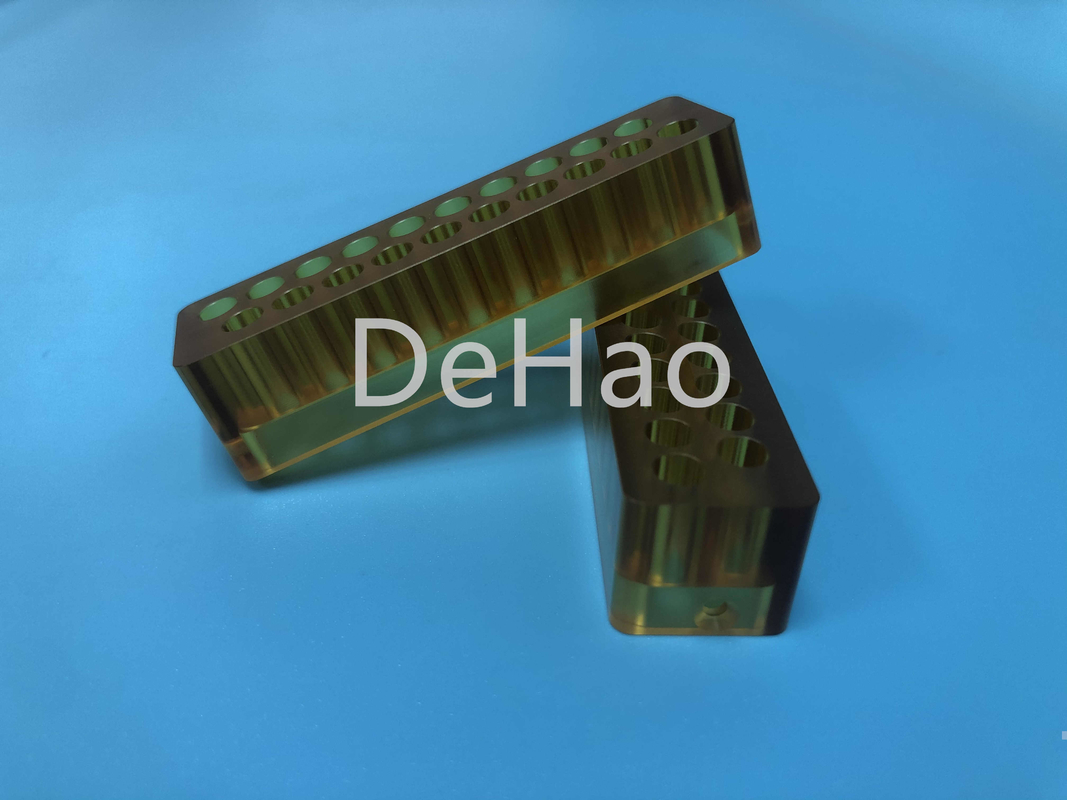

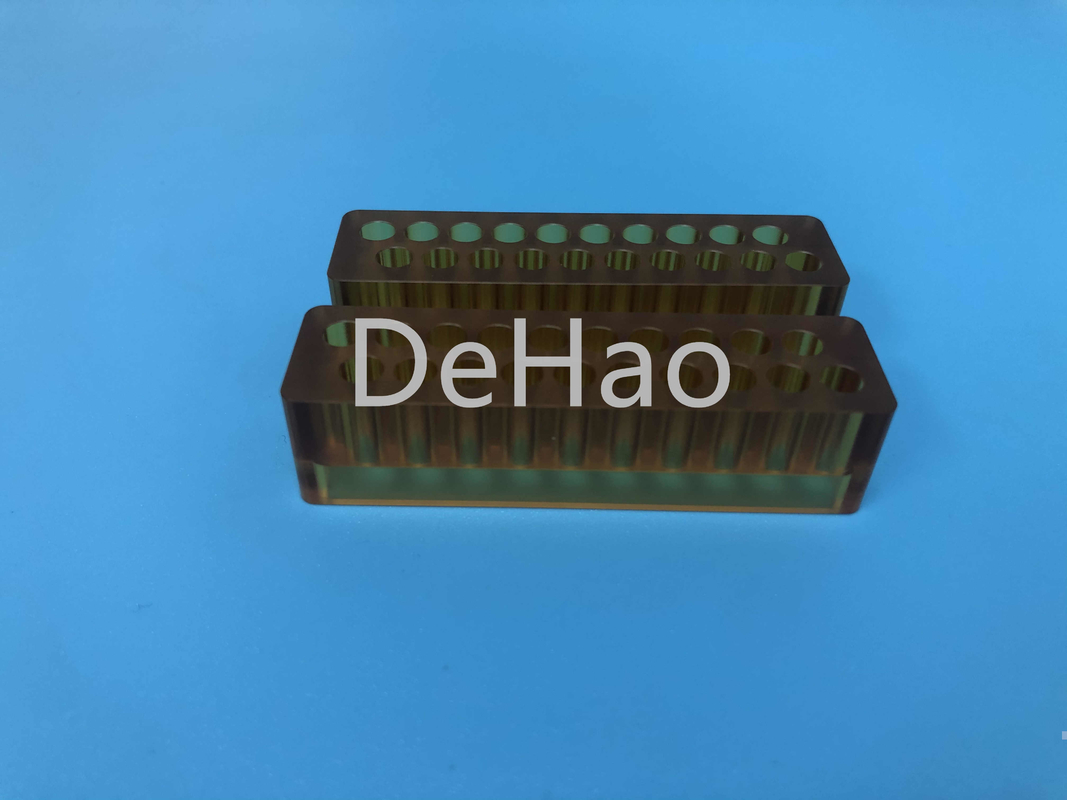

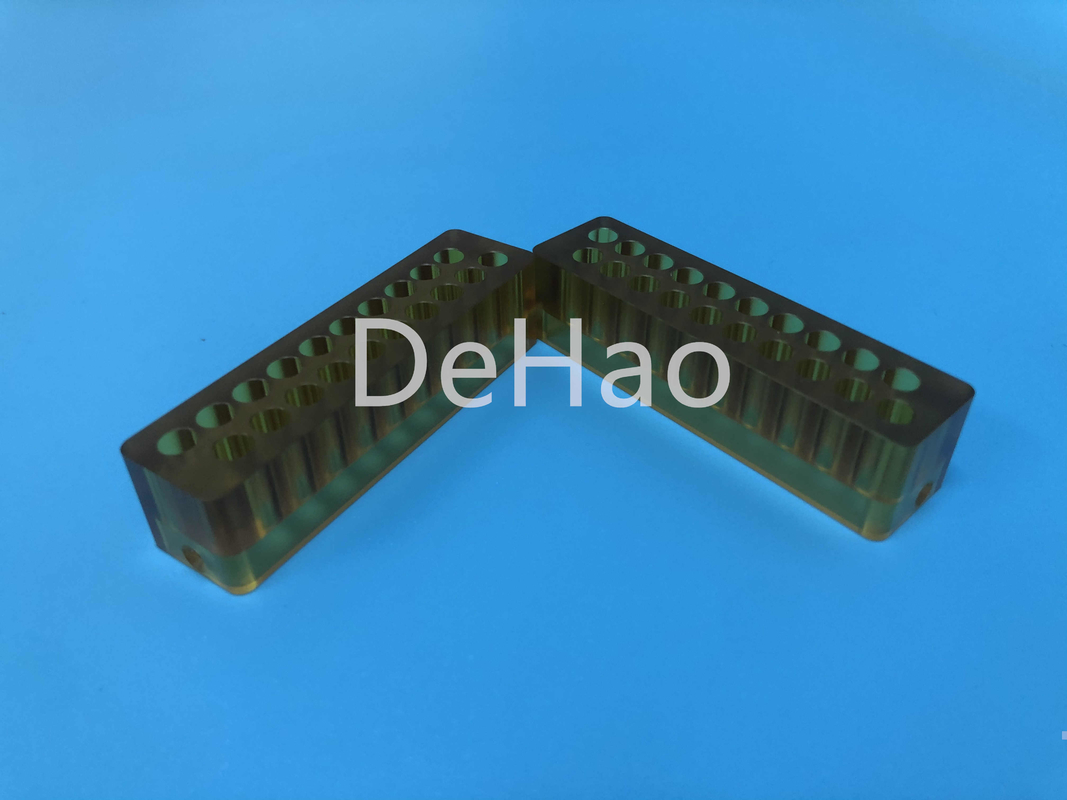

PEI Connector Components

,Machined Ultem Parts

,Ultem 1000 PEI Connector

-

Volume Resistivity10^14 Ohm-cm

-

Impact Strength2.0 Ft-lb/in

-

Max Operating Temperature400°F

-

Thermal Conductivity2.0 BTU-in/hr-ft²-°F

-

Tensile Strength7,000 Psi

-

Flexural Strength14,000 Psi

-

Tensile Modulus350,000 Psi

-

ColorNatural

-

Place of Originkunshan

-

Brand Namedehao

High Quality Machined Ultem Parts PEI Connector Components Ultem 1000

Product Description:

PEI connector components are made of Polyetherimide (PEI) material. PEI is a high-performance engineering plastic known for its excellent mechanical properties, thermal stability, and chemical resistance.

PEI connector components are commonly used in applications that require high temperature resistance, electrical insulation, mechanical strength, and chemical resistance. Here are some key features and advantages of PEI connector components:

- High temperature resistance: PEI material exhibits exceptional heat stability, allowing it to maintain its performance in high-temperature environments. This makes PEI connector components suitable for applications that require high temperature resistance, such as aerospace, automotive, and electronics industries.

- Electrical insulation: PEI is an excellent electrical insulating material, effectively preventing electrical conduction. Therefore, PEI connector components can be used in electronic devices and circuit boards that require electrical insulation to avoid current leakage or interference.

- Mechanical strength: PEI possesses outstanding mechanical strength and rigidity, enabling it to withstand high forces and pressures. This makes PEI connector components well-suited for applications that demand high strength and durability.

- Chemical resistance: PEI material exhibits good resistance to chemical corrosion, making it resistant to various chemical substances. This makes PEI connector components suitable for applications in chemical processing, medical devices, and laboratory equipment.

Features:

- Product Name: Ultem PEI

- Tensile Strength: 7,000 Psi

- Tensile Modulus: 350,000 Psi

- Thermal Conductivity: 2.0 BTU-in/hr-ft²-°F

- Impact Strength: 2.0 Ft-lb/in

- Volume Resistivity: 10^14 Ohm-cm

- Machined Ultem parts for high temperature applications

- High strength machined Ultem parts for rugged applications

- High temperature machined Ultem parts for extreme conditions

- High strength machined Ultem parts for demanding applications

Technical Parameters:

| Property | Value |

|---|---|

| Dielectric Constant | 3.2 |

| Density | 1.27 g/cm³ |

| Impact Strength | 2.0 ft-lb/in |

| Material | Ultem PEI |

| Max Operating Temperature | 400°F |

| Heat Deflection Temperature | 280°F |

| Volume Resistivity | 10^14 Ohm-cm |

| Color | Natural |

| Dielectric Strength | 400 V/mil |

| Flexural Modulus | 400,000 psi |

Applications:

dehao Ultem PEI is a High Temperature Ultem Polymer with excellent mechanical and electrical properties, making it an ideal choice for applications that require high temperature resistance and low outgassing. It is a versatile material that can be machined into parts for a wide range of applications.

dehao Ultem PEI has an extremely high tensile modulus of 350,000 Psi, allowing it to withstand extreme temperatures up to 400°F. It also has superb impact strength of 2.0 Ft-lb/in, as well as an impressive volume resistivity of 10^14 Ohms-cm and thermal conductivity of 2.0 BTU-in/hr-ft²-°F.

dehao Ultem PEI is an ideal choice for applications that require high temperature resistance, low outgassing, and machined parts, such as aerospace, medical, and automotive components. It is a lightweight and durable material that can withstand extreme temperatures and harsh conditions.

Customization:

We provide custom machined Ultem parts in a variety of shapes and sizes, backed by our brand name dehao, with a place of origin Kunshan. Our Ultem PEI parts are strong and durable, with a maximum operating temperature of 400°F, a dielectric constant of 3.2, an impact strength of 2.0 Ft-lb/in, and a water absorption of 0.2%. Our custom Ultem PEI machining services are perfect for high temperature applications, providing a superior alternative to traditional machined parts.

FAQ:

- Q: What is Ultem PEI?

- A: Ultem PEI, produced by dehao from Kunshan, is an engineering thermoplastic material offering superior performance in terms of chemical resistance, heat resistance, flame retardancy, electrical insulation, and dimensional stability.

- Q: What are the benefits of Ultem PEI?

- A: Ultem PEI offers excellent mechanical and thermal properties, chemical resistance, flame retardancy, and electrical insulation. In addition, it is highly resistant to wear and tear, and offers excellent dimensional stability.

- Q: What industries is Ultem PEI used in?

- A: Ultem PEI is widely used in the automotive, electrical, medical, and aerospace industries, due to its superior performance and versatility.

- Q: What are the product features of Ultem PEI?

- A: Ultem PEI is a strong and lightweight thermoplastic material with high strength, stiffness, and excellent electrical properties. It is also heat resistant, flame retardant, and highly resistant to wear and tear.

- Q: What are the applications of Ultem PEI?

- A: Ultem PEI is used in a wide variety of applications, including automotive components, electrical components, medical devices, and aerospace components.